Semiconductor Market 2021

- Junto HKIS

- Dec 16, 2021

- 3 min read

Katherine Ashley Chen

December 16, 2021

Semiconductor factors

The semiconductor-making process involves giant factories, dust-free rooms, multi-million dollar machines, lasers, and the building block of the chip, silicon. Additionally, labor consists of unskilled workers, skilled workers (such as engineers), and machine labor. Other supply costs include expensive facilities that take significant amounts of time and money to build, as well as services such as chip-packaging, which TSMC outsources.

Market labor situation

Although the supply of unskilled workers in the assembly line is relatively unimpacted, there is a shortage of qualified semiconductor engineer skilled workers. In 2018, reports showed that thousands of semiconductor manufacturing jobs were left unfilled, most notably at the top of the supply chain, where workers need years of specialized training. The shortage of skilled workers is compounded by the fact that the cost of skilled labor in the semiconductor industry is quite high, as the semiconductor industry employs more workers with college degrees than manufacturing and all other industries. Unsurprising, as a whole, average semiconductor labor pay is already higher than the average at all educational attainment levels. Additionally, 2/3rds of firms report rising labor costs, and most expect this to continue well into the future.

Even though the semiconductor industry has a high cost of labor and thus a higher wage for skilled workers, more specialized industries such as consulting and investment banking offer even higher wages. Thus comparatively, semiconductor industries have a lower wage for skilled workers. This low wage creates a shortage of skilled workers, as the educated workers with the same qualifications are lured to those industries, and prefer to go on career paths that seem more accessible and opportune.

Although there are no specific statistics for Taiwan Semiconductor Manufacturing Company (TSMC), it can be assumed that because they make up such a significant percentage of the semiconductor manufacturing industry, they also experience the same situation in the labor market of skilled workers.

Social Impact

Semiconductor chips are used from everything from microwaves to cars to laptops. Since electronics create such convenience in our modern society, semiconductor manufacturing and manufacturing firms create a net positive impact and generate a marginal social benefit (MSB) higher than the marginal private benefit (MPB) that the firm experiences. This positive externality creates a situation in which there is an underallocation of resources towards semiconductor production. To match this, the government should implement subsidies or incentives to encourage firms to produce at the socially optimal quantity. In doing this, the government also makes up for the loss the firm would otherwise experience if they produced at the socially optimal quantity and price.

Government intervention

In order to incentivise producers to produce a higher quantity and to make up for losses, the Taiwanese government has begun investing and donating resources (total US$300 million) to feeder universities in order to provide more resources for the production and research of semiconductor chips. With these subsidies, TSMC and the market as a whole has moved more towards producing at the socially optimal quantity and price.

Pandemic impact

During the pandemic, the demand for consumer electronics and household electronics increased, and as a result, the demand curve for semiconductor chips shifted towards the right. Due to the higher demand, both the equilibrium price and quantity of semiconductor chips increased, and to match this demand, the firm hired additional skilled workers at a higher wage. This is because to hire a higher number of workers, TSMC must therefore also increase the wage of the workers. Although the workers are skilled, they still have other options, such as banking, consulting, education or anything else that a college degree may be useful for, and therefore may choose other options if the TSMC wage does not also increase.

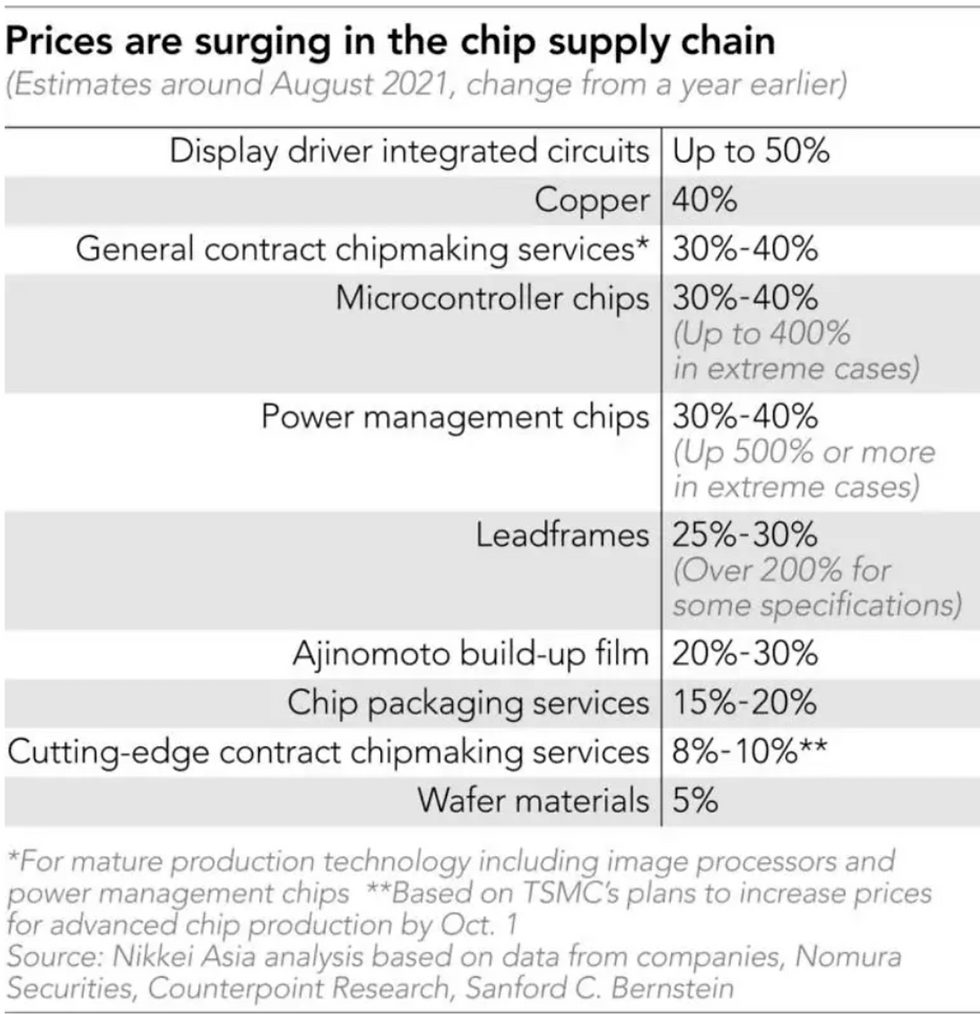

Commodities Trends

In addition to unskilled and skilled workers, semiconductor manufacturing also requires silicon, germanium, and other pure elements. However, there has been a rise in the cost of silicon and germanium, which has caused the overall supply of the semiconductor market to shift inwards. Since TSMC makes up such a huge portion of the semiconductor market, its supply has also shifted inwards. As you can see in the graph, this causes the equilibrium quantity to decrease while the equilibrium price increases. This impacts the quantity of labor hired by TSMC, as a lower quantity of semiconductor chips means a lower quantity of labor that is necessary to produce the chips.

Rise in other costs

Other than raw materials and labor, prices in other required services such as chip packaging services have also risen a substantial amount, affecting supply the same way as it is a rise in input cost. The supply curve has further shifted to the left for the market and TSMC, which has made TSMC require an additionally fewer quantity of workers.

Comments